Explore solutions built for your industry

Our customer-proven solutions monitor medications and food inventories for some of the most recognizable names in the industries of healthcare, food service, and transportation, and logistics. See how our solutions adapt to your industry needs.

SEE SOLUTIONSKroger Health Strengthens Compliance Visibility with SmartSense

Watch The VideoLEARN

Questions? Call +1 (866) 806-2653 to speak to our experts.

Schedule demoQuestions? Contact us.

Call +1 (866) 806-2653 to speak with our experts or get started with a demo.

CONTACT USAbout Us

SmartSense was created to use the power of the Internet of Things (IoT) to help our customers protect the assets most critical to the success of their business.

See our storyCONNECT. PROTECT. RESULTS.

Questions? Call +1 (866) 806-2653 to speak to our experts.

Schedule demoPlease select your login

January 25, 2018

Here’s Why Continuous Monitoring Keeps Your Inventory Safe

Food safety and pharmaceutical storage are two applications where knowing the temperature of the storage area for a product is critical to ensuring its safety and viability. Produce will spoil quicker when it’s not cooled during storage, which can lead to quality issues in the freshness and taste of the final product. Even more seriously, this creates a risk of making consumers sick if bacteria are able to colonize it and pharmaceuticals can lose potency or become unsafe if not stored in suitable conditions.

In many places, regulations are in effect that require retailers to be able to demonstrate that they have safely stored products. These regulations vary from location to location; some only require twice-daily readings, while others require strict continuous temperature monitoring. Typically, this is a manual task where temperature readings are recorded using pencil and paper and must be accessible in the case that an audit is performed. The manual nature of the collections and the volume of paper records that result are two reasons that collecting several measurements per day is impractical without automation.

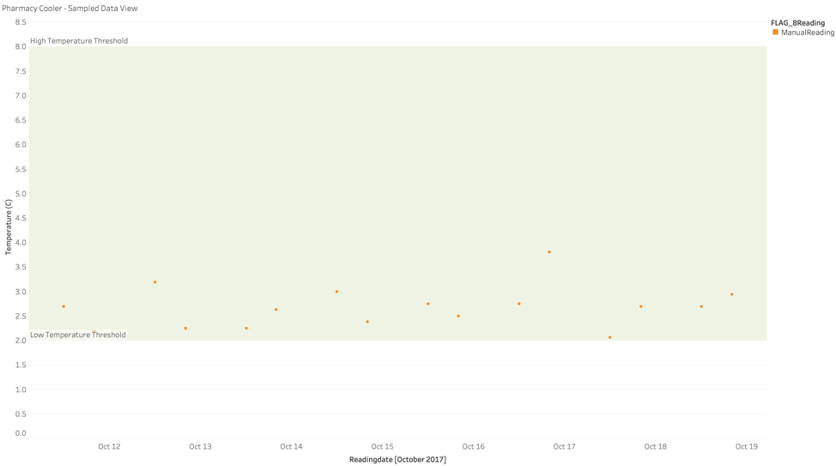

In the figure below, we show what a pharmacist would see if they sampled the temperature from an actual client’s pharmacy cooler we monitor twice daily at the same time:

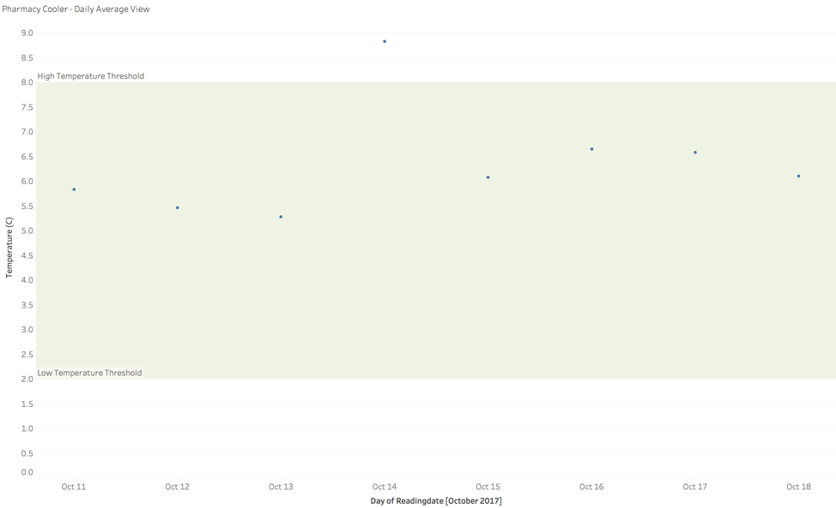

Based on this data, the pharmacist would be confident storing product in the cooler. If the same fridge was monitored continuously and a daily average score examined, here’s what it would look like:

Here, the pharmacist could conclude that their cooler is generally doing a good job, but it had an issue on October 14.

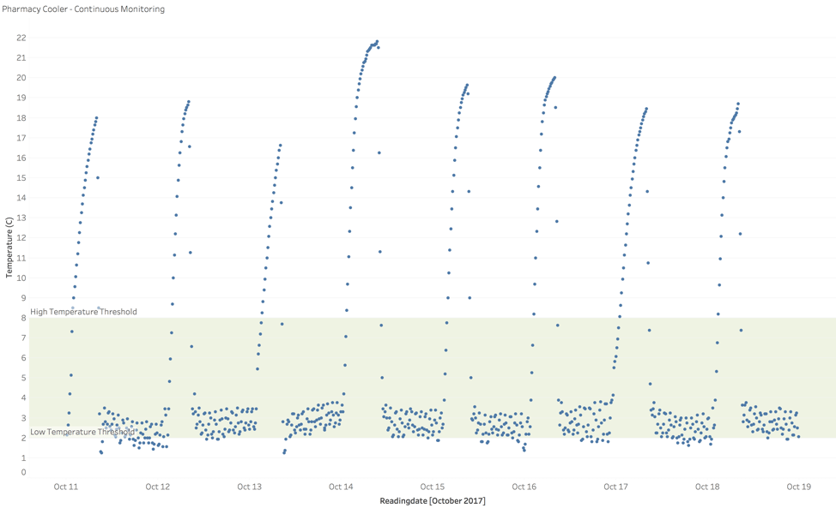

In fact, when looking at the full temperature history for this pharmacy cooler throughout the week, we see that sampling or averaging have missed the most significant events:

Instead of being a robust cooler, it turns out that every day this pharmacy cooler was experiencing significant “excursions”—time periods where the temperature strays outside of the desired bounds.

After investigating the cause of this issue, it turned out that the cooler was plugged into an outlet that was turned off nightly! Since this team traditionally only sampled the temperature twice a day—and by the time they arrived in the morning, the temperatures were back in a reasonable range—they didn’t realize that the product stored in this cooler was regularly being exposed to temperatures far out of their recommended storage range.

Not only were we able to expose this issue for this particular unit as we implemented continuous monitoring and alerting, but our Analytics team was able to develop an automated approach to detecting other coolers and freezers with consistent daily excursions that belied loss of power. Using this tool, we identified more than 65 other assets that were similarly plugged into outlets that did not provide 24-hour continuous power. Each of these represented a significant source of risk that their prior operations, while consistent with regulatory temperature requirements, were not able to catch.

This data shows the true power of the Enterprise Internet of Things (IoT). It merges modern technologies to to create whole new capabilities, including:

- ubiquitous sensors (one in each cooler and each freezer for this client)

- analytics (characterizing the issue in a way that an automated process can detect additional cases)

- big data (streaming the data into our cloud warehouse and having the tools to rapidly apply our analytics to it)

Subscribe to Our Blog!

Interested to learn more about our remote monitoring and analytics for clients? Subscribe to our blog and get the next post straight to your inbox.

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.

CONNECT. PROTECT. RESULTS.

Learn how our complete critical

environment monitoring solution will help you

connect and transform your business.

Call +1 (866) 806-2653 to speak with our industry

experts or get started by

requesting a demo.