Written by SmartSense

Key takeaways

Many pharmacies, medical offices, and health clinics manually monitor temperature twice per day using a paper log. If the temperature at the time of the reading is within the desired range, 36°F - 46°F (2°C - 8°C) for refrigerators, -50°C - -15°C (-58°F - +5°F) for freezers, no action is taken.But what happens during the day when pharmacists and medical professionals are opening and closing the door? The room temperature may be higher or lower due to automatic control settings, or based on the number of people in the area. What about the operating cycles of the refrigerators and freezers? Twice per day, manual temperature readings cannot capture this information.

One solution being deployed by major pharmacy chains is remote temperature monitoring using wireless sensors. Unlike manual temperature logs, remote monitoring can be configured to record temperature at regular intervals, every 15 minutes for example. Temperature logs are then sent to a cloud-based remote monitoring platform and can be viewed in real-time.

A study of 15,000 refrigerators and freezers across a major pharmacy chain, highlighted the power of remote temperature monitoring. Initial temperature readings showed almost 20% were operating above or below the range and needed adjustment to bring them into compliance.

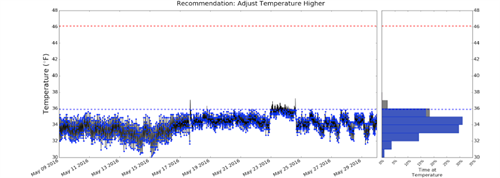

Needs Adjustment: Adjust Higher to bring into control range.

In the image above an Rx refrigerator was operating below the required lower limit of 36°F (2°C), most of the time. Fluctuations from cooling cycles and door openings are visible in the data. These changes in temperature would have gone unnoticed with only twice per day manual monitoring.

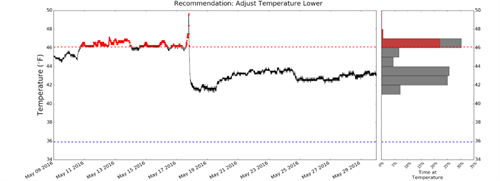

In the image below a second Rx refrigerator was shown to be operating above the required limit of 46°F (8°C), most of the time. Again, twice per day manual temperature monitoring would not have detected this issue. Remote monitoring helped bring these issues to the surface. In this image, the results of the adjustment are apparent. With real-time data, they were able to make the necessary temperature adjustments and see immediate results.

Needs Adjustment: Adjust Lower to bring into control range.

Remote monitoring provides pharmacies with a complete picture of their equipment temperatures. And enables them to take control and make immediate adjustments when necessary, ensuring medication quality and safety.

Topics:

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.