Written by SmartSense | Food Safety, HACCP

Key takeaways

Grocery stores offer a wide variety of foods, including many perishables that require tight temperature controls. Fridges, freezers, reach-ins, and bunkers that hold these sensitive foods must be checked throughout the day, taking time away from team members from ensuring good experience for their customers. Manual temperature checks, typically done with pen and paper, are error-prone, easily forgotten, increase compliance risk, and lead to unnecessary food waste in the event of a temperature failure. This presents a significant opportunity to leverage technology to improve operational efficiency, reduce waste, and improve compliance efforts.

The Challenges with Perishables & Temperature

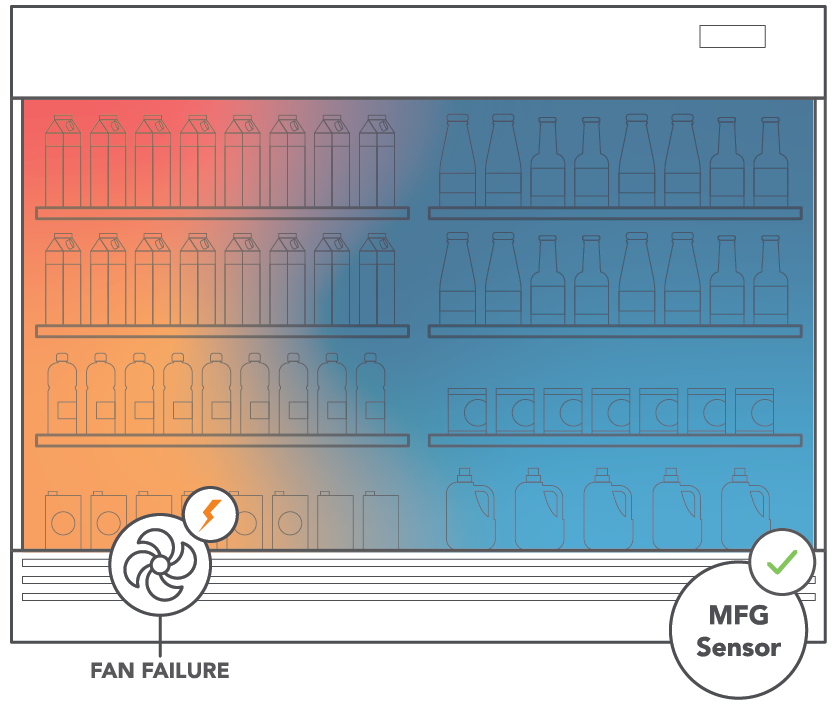

Supermarkets can maintain hundreds of refrigerators, freezers, and cases that hold temperature-sensitive perishables. Perishables account for 52.63% of all grocery sales, making this category of food valuable to every grocer. A temperature excursion of just a few hours can force grocers to discard thousands of dollars worth of food, leading to unnecessary expenses and undue environmental damage. Catching the excursion before its able to cause harm is challenging, however. In the case of a fan failure, manufacturer sensors may not be placed in an ideal location to identify a change in temperature.

Depending on where it’s installed, manufacturer sensors can miss a fan failure, and cause food to go bad.

By the time the warm air has reached the original sensors, it may already be too late! Some foods, such as ice cream or raw meat, need to be kept at the proper temperature at all times, else they lose quality or can no longer be considered safe to eat. Additionally, typical manufacturer sensors may not provide the ability to send a notification when an excursion is detected, leaving the discovery to whoever happens to perform the next temperature check. Responding to a temperature reading that is out of range in a timely manner is incredibly important.

Manual Temperature Checks

Monitoring temperatures throughout a grocery store has typically required someone physically walking over to each individual case. This pen and paper process of checking temperature leads to a host of problems. Manual temp checks take up valuable employee or manager time that could be spent interacting directly with the customer.

Using pen and paper is error-prone. Employees may mistakenly misread a sensor, incorrectly write down a number in a rush, or write so haphazardly that it is near-impossible to read in the case of an audit. Manual temperature checks can also be easily skipped. Whether intentional or not, missed temperature checks can wreak havoc if they are not addressed in time. From spreading disease as a result of foodborne illness, to quality issues, there is much at risk if equipment does not hold perishable foods at temp.

Maintaining Compliance

There are countless compliance laws on the books for regulating food storage. These laws are partly due to Upton Sinclair’s The Jungle, which included a chapter on how contaminated meat products were processed, doctored by chemicals, and mislabeled for sale to the public. Since then, federal agencies such as the FDA and USDA have developed regulatory systems for ensuring that the food we consume is safe to eat.

One of the primary ways that these agencies ensure compliance in the businesses they oversee is to perform audits either at random or for suspected perpetrators. These audits will review a number of factors, one being the temperatures at which perishable foods have been held. In reviewing these audits, compliance officers will inevitably notice if temp checks were missed or indecipherable. Either case can lead to a failed inspection, adding unnecessary expenses.

Managing Food Waste

Food waste is largely unavoidable for any supermarket. As outlined above, foodborne illness or degrade in quality can lead to a need to discard food.

Average value per case in a grocery store. Source: customer study performed by SmartSense.

SmartSense conducted a study with grocery stores around the country, and found the average case holds upwards of $6,000 worth of perishable food. Because of this, a single refrigeration failure can lead to significant loss. At any point in time, day or night, a temperature failure can lead to thousands of dollars worth of loss, all because the excursion was not identified in time.

These costs do not consider the impact that food waste has on our environment. A recent Washington Post article pointed out that “if food waste were a country, it could come in third after the United States and China in terms of impact on global warming.” Granted, this includes many areas that consumer grocers have no control over, but highlights the point that we have an obligation to reduce food waste in any way we can.

Leveraging Technology for Perishables

So what is to be done? Thankfully, the problems presented from storing perishables can largely be addressed using IoT. Wireless temperature monitoring was not possible before small-form factor sensors and high-speed wireless communication became a reality. Now, wireless sensors can capture temperature remotely, leading to previously unavailable visibility.

By eliminating manual temperature checks, grocers stand to improve their operational efficiency, and give back more time to employees so that they can interact directly with customers. Remote temperature monitoring can simplify compliance efforts. By automatically recording temperature at regular intervals throughout the day, grocers can eliminate the possibility that a check gets missed. Finally, identifying temperature excursions in real-time enables grocers to reduce food waste. They can be notified that temps are reaching the danger zone, and can respond appropriately.

Using the power of IoT, manual temperature checks can be eliminated, temperature excursions identified before they cause irreparable harm, and simplify compliance in case of an audit.

Subscribe to Connected Insights!

Subscribe to our blog to get regular email updates on food safety, pharmacy safety, and supply chain insights.

Topics: Food Safety, HACCP

Other Suggested Posts

How Sales & Operations Planning Decisions Prevent Food Waste in the Supply Chain

Food waste along the wholesale and retail supply chain is often blamed on downstream operations failures. Its roots, however, oftentimes lie upstream. As we ...

How to Improve QSR Operations with IoT-Enabled Tools for Deskless Workers

As the demand for convenient, fast, and quality food continues to rise, small QSR chains face increasing pressure to deliver exceptional customer experiences ...

Why Customer Success Makes the Difference in Your Condition Monitoring Program

If your business objective is to implement an efficient and successful condition monitoring program, gone are the days of “set it and forget it.” Today’s savvy ...

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.