Written by SmartSense | Food Safety

Key takeaways

Keeping food free of pathogens should be a no-brainer. Since microorganisms grow best in warm conditions, the goal is simply to ensure proper storage that keeps food within a safe temperature range. Common sense, right? But refrigerators and freezers aren’t perfect. They can break down, power outages can turn them off, and busy employees can accidentally leave a door open. That’s why it’s important to have a temperature monitoring system in place to alert you if your refrigerator or freezer gets out of a safe range.

Food Safety Monitoring for Quality & Compliance

Whether you’ve implemented your own HACCP plan and/or follow FSMA guidelines, you know the risks of breaking the cold chain. Food producers, shippers, trucking companies, and other commercial establishments work together to coordinate and streamline necessary procedures to meet compliance, maintain quality, and protect consumers from foodborne illness.

Once you’ve identified the hazards within your own establishment, the next step is controlling them. Best practices should emphasize monitoring temperature in mission-critical areas such as:

- Environmental conditions during transit

- Storage environments

- Cooking temperatures

- Holding temperatures

- Serving temperatures

Also, to make your food safety process as foolproof as possible, install continuous temperature monitoring devices in your establishment’s cooling and heating equipment, including:

- Walk-ins

- Freezers

- Stand-alone refrigerators

- Makelines

TempAlert’s Temperature Monitoring Solution

TempAlert’s temperature monitoring solution is both automatic and easy to deploy. Our plug- and-play sensors combine with a sensor management platform to provide real-time information about the temperature of products and storage conditions. Our Bluetooth Probe, Insights Dashboard, and Wireless Sensors are used by food producers, trucking companies, distributors, warehouses, restaurants, K12 & university dining, and fast casual chains.

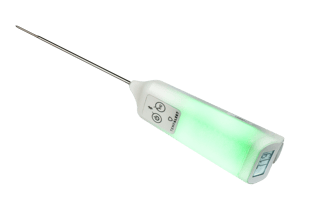

Bluetooth Probe

A Bluetooth food probe is the perfect tool for measuring the temperature of ingredients within your makeline. Using a digital checklist to manage your daily HACCP process, you can record the temperature of a variety of ingredients such as sour cream, tomatoes, cheese, and more to ensure your makeline ingredients are within safe temperature ranges.

Our Bluetooth Probe can be used for checking hot or cold food items. It integrates with any food safety checklist running on tablets or mobile phones enabled with Bluetooth 4.0. Our probe has intuitive lighting effects to let you know right away if the temperature is within a safe range by lighting up green, and red for out of range.

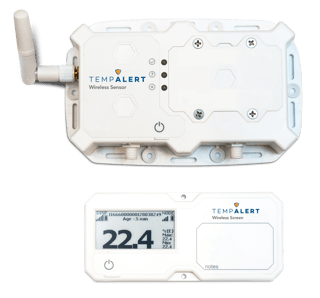

Wireless Sensors

It’s also important to monitor the temperature of the equipment in your restaurant such as walk-ins, freezers, lowboy coolers, and more. Keeping food stored at proper temperatures is the key to keeping your consumers safe from foodborne illness. By using wireless sensors, you can monitor the temperature of your refrigerated environments in real-time.

Our Wireless Sensors offer 100% wire-free installation with wireless screens that can be placed directly in fridges and freezers. Centralized configuration is provided through our Insights Dashboard.

Insights Dashboard

Imagine if an employee accidentally leaves the door open to your walk-in fridge, compromising all of the products inside. You would want to be notified as soon as possible that your fridge went out of range. Using a software program, such as our Insights Dashboard, enables you to set alerts and see the real-time temperature ranges of your equipment.

Our Insights Dashboard delivers real-time oversight of your monitoring initiatives. It provides visibility into compliance and site performance, enables a collaborative approach to monitoring, and issues automated email reports identifying sites with the greatest food safety risks.

With the TempAlert solution, you can improve product quality, increase operational efficiency, and ensure compliance, all while reducing liability and risk.

To learn more about our products and request a quote, contact TempAlert today.

Topics: Food Safety

Other Suggested Posts

How Sales & Operations Planning Decisions Prevent Food Waste in the Supply Chain

Food waste along the wholesale and retail supply chain is often blamed on downstream operations failures. Its roots, however, oftentimes lie upstream. As we ...

How to Improve QSR Operations with IoT-Enabled Tools for Deskless Workers

As the demand for convenient, fast, and quality food continues to rise, small QSR chains face increasing pressure to deliver exceptional customer experiences ...

Why Customer Success Makes the Difference in Your Condition Monitoring Program

If your business objective is to implement an efficient and successful condition monitoring program, gone are the days of “set it and forget it.” Today’s savvy ...

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.