Written by SmartSense | Food Safety, Supply Chain

November 11, 2021

Our customer-proven solutions monitor medications and food inventories for some of the most recognizable names in the industries of healthcare, food service, and transportation, and logistics. See how our solutions adapt to your industry needs.

SEE SOLUTIONSCall +1 (866) 806-2653 to speak with our experts or get started with a demo.

CONTACT USSmartSense was created to use the power of the Internet of Things (IoT) to help our customers protect the assets most critical to the success of their business.

See our storyNovember 11, 2021

Written by SmartSense | Food Safety, Supply Chain

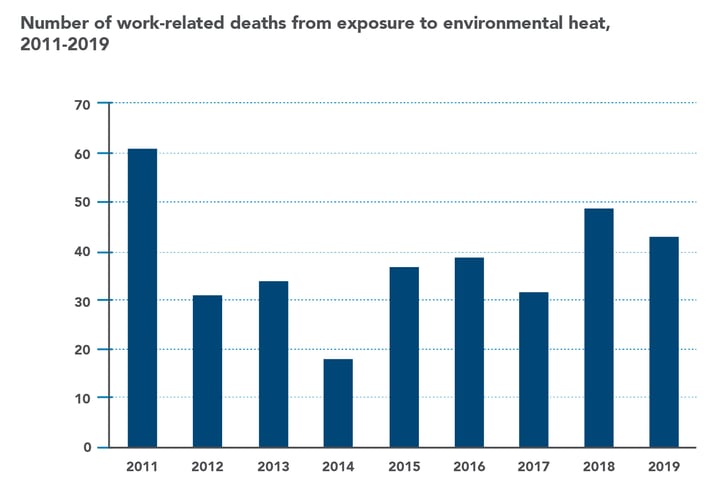

While the nation transitions into months of cooler weather we only need to look back to the previous summer to acknowledge that our world continues to get much warmer with July 2021 being the hottest month ever recorded. On-the-job illness related to the lack of facility heat index monitoring is now as threatening as the COVID-19 pandemic to the health and safety of food service workers.

Employee Heat Stress Data

The statistics are alarming:

“Throughout the nation, millions of workers face serious hazards from high temperatures both outdoors and indoors. Amid changing climate, the growing frequency and intensity of extreme heat events is increasing the dangers workers face, especially for workers of color who disproportionately work in essential jobs in tough conditions.” — U.S. Department of Labor Secretary Marty Walsh.

A warming environment can cause lost work hours and productivity, resulting in lost wages for workers. The Atlantic Council's Adrienne Arsht-Rockefeller Foundation Resilience Center estimates heat stres illness currently costs business at least $100 billion annually – a figure likely to double by 2030 and quintuple by 2050.

Up until now, the Department of Labor’s Occupational Safety and Health Administration (OSHA) has pursued charges against employers who do not prevent heat-related illness primarily in outdoor environments. Then two years ago, the public interest group Public Citizen and 111 other safety and labor groups urged legislators to create a federal standard for protecting workers from heat stress for both outdoor and indoor workers.

In response to these growing demands, in September the White House announced expanded efforts by the U.S. Department of Labor to address heat-related illness in warehouse facilities and outdoors. As part of the president’s interagency effort and commitment to workplace safety, climate resilience, and environmental justice, OSHA is initiating enhanced measures to protect facility workers in hot spot environments and reduce the dangers of ambient heat.

To emphasize its concern and take necessary action, OSHA is implementing an enforcement initiative on heat-related hazards, developing a National Emphasis Program on heat inspections, and launching a rulemaking process to develop a workplace heat standard. In addition, the agency is forming a National Advisory Committee on Occupational Safety and Health Heat Injury and Illness Prevention Work Group to share best practices to protect workers.

“While agricultural and construction workers often come to mind first when thinking about workers most exposed to heat hazards, without proper safety actions, sun protection and climate-control, intense heat can be harmful to a wide variety of workers indoors or outdoors and during any season. " -- Acting Assistant Secretary for Occupational Safety and Health Jim Frederick.

OSHA will begin to draft heat index rules for the food service industry, especially targeting agriculture, restaurants, and meatpacking. The agency is currently creating new heat standards for warehouse workers in warehouses, distribution centers, and manufacturing plants lacking climate-controlled environments. Starting in October, OSHA will also start drafting additional heat safety standards for restaurant kitchens.

Initiate onsite investigations of heat-related complaints and employer-reported illnesses

Instruct safety and health officers to conduct an intervention when they observe employees working strenuously in hot conditions

Expand the scope of inspections at worksites where evidence indicates the presence of heat-related illness

The OSHA heat stress standard will most likely require employers to monitor employee acclimatization, including temperatures and humidity levels. These new regulations would require manufacturing worksites without air conditioning to install sensors to detect when conditions exceed healthy levels.

OSHA indicated that it would help employers protect their workers rather than seek penalties. The agency will consult with employers to encourage its “Working in Outdoor and Indoor Heat Environments” best practices, including:

OSHA’s new heat standards align with the FDA’s New Era of Smarter Food Safety, which encourages businesses to implement digital heat monitoring technology to create a safer food system. FDA emphasizes that sensors, artificial intelligence, and the Internet of Things better predict, detect, and respond to safety issues when they occur. Of particular relevance to the OHSA heat standards are the following objectives in the FDA blueprint:

SmartSense by Digi Heat Monitoring Sensors Help Meet OSHA Standards

The SmartSense Facility Heat & Humidity Monitoring solution can be implemented to help food service businesses ensure that they meet the new OSHA heat standards. It combines wireless sensors with remote monitoring software to measure temperature and humidity in critical environments such as restaurant kitchens, depots, warehouses, processing plants, and distribution centers.

As ambient temperatures fluctuate and rise above 80 degrees, safety managers will receive a real-time alert so that they can take immediate remedial action to prevent heat-related illness. And our digital loggers will capture real-time data to provide visibility into site performance for regulatory compliance, improved accountability and risk management. Visit our SmartSense by Digi website for more details.

Stay up-to-date on the evolution of IoT connectivity.