Written by SmartSense | Food Safety, FSMA, Supply Chain

Key takeaways

Real-time Temperature Data Is Essential

As a carrier of perishable products, food distributors now have a legal obligation to ensure goods in their custody and control are not “adulterated” via the Food Safety Modernization Act (FSMA). According to the FDA, the FSMA is meant to prevent unsafe practices from occurring during transportation, “such as failure to properly refrigerate food, inadequate cleaning of vehicles between loads, and failure to properly protect food.” (U.S. Food and Drug Administration)

Refrigeration in motion remains the biggest challenge of meeting FSMA compliance. Most organizations are meeting compliance by investing in means to ensure temperature integrity, including well-insulated trailers, elaborate door seals, modern refrigeration units, and the latest and greatest bulkhead applications. The transportation industry invests millions of dollars to help ensure best practices are met, but what steps are being taken to ensure these investments are utilized once that load departs?

Take Control of Fleet Temperature Monitoring

With the rapid evolution of cellular networks throughout the last 10 years, it’s now possible and practical to monitor mobile assets in real time—and notify stakeholders of dramatic exceptions in transit. Whether you’re a fleet owner or a consumer of products delivered by fleet, the universal hope is that those responsible for food quality are making reasonable efforts to do their part. After all, a refrigerated trailer is essentially a warehouse on wheels.

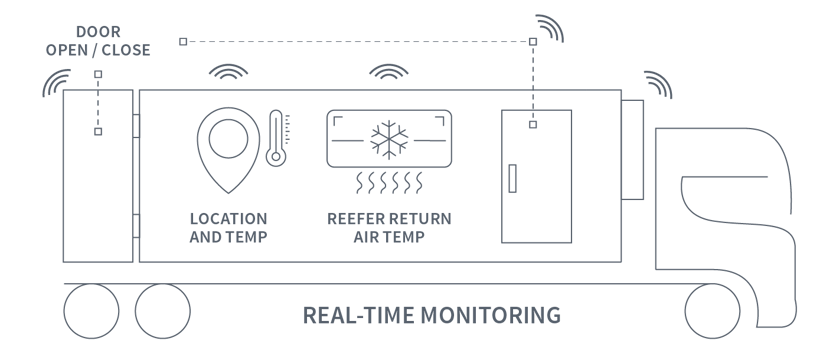

It’s widely known within the industry that driver behavior has the most dramatic influence on temperature integrity in transport. Fleet managers must be complying with FSMA by utilizing at least one of the two possible avenues to monitor transport refrigeration: the Transport Refrigeration Unit (TRU), or sensory data within refrigerated compartments of the truck or trailer.

Real-time information is key to ensure compliance. The TRU approach reveals critical information to technicians investigating issues that distract from cooling or heating compartments. But does not provide a comprehensive, real-time view of the important data and is certainly not something the fleet manager can control.

What do fleet managers need to know in real-time?

- Is the refrigeration unit on?

- Is the air temperature from the TRU adequate for the product being hauled?

- Are the compartment doors open too many times or for too long?

- Are doors opening outside of planned delivery locations?

- What is the temperature of compartments holding product at delivery time?

These are all questions that real-time, sensor-based applications can answer because they’re always on and always reporting. In comparison, systems that rely on the TRU only provide information when the TRU is turned on, leaving many gaps in the data and providing hundreds of codes and alerts considered more appropriate for TRU technicians than fleet managers.

Achieve Real-time Monitoring With the Internet of Things

Managing by exception, independent wireless sensors are located according to fleet requirements and allow distributors to translate data specific to a point or zone. These sensors can act as an independent audit of TRU performance while adding additional points that meet internal requirements. When validating sensitive wireless data, products like SmartSense’s provide comprehensive views of all points and all zones, whereas TRU centric data isolates information at the TRU with sensors embedded in the machine.

It’s essential for these systems to be able to monitor multiple sensor points to bring attention to exceptions to Standard Operating Procedure (SOP). In the event that any of the doors are left open, temperature rises or falls out of acceptable range, or there is an equipment failure, managers are notified and are able to react.

The buzz-term “IoT,” or Internet of Things, is now appropriate for food distributors. You could even call it the “Internet of Transportation.” Fleets using systems like SmartSense’s enjoy the benefits of being able to react in real-time as well as the extra assurance of having documentation post-trip, exceeding FSMA requirements. The data is always available so that you can reach back into reports when you need them.

To learn more about FSMA and how you can easily meet compliance, visit our website and subscribe to our blog.

Other Suggested Posts

How Sales & Operations Planning Decisions Prevent Food Waste in the Supply Chain

Food waste along the wholesale and retail supply chain is often blamed on downstream operations failures. Its roots, however, oftentimes lie upstream. As we ...

How to Improve QSR Operations with IoT-Enabled Tools for Deskless Workers

As the demand for convenient, fast, and quality food continues to rise, small QSR chains face increasing pressure to deliver exceptional customer experiences ...

Why Customer Success Makes the Difference in Your Condition Monitoring Program

If your business objective is to implement an efficient and successful condition monitoring program, gone are the days of “set it and forget it.” Today’s savvy ...

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.