Written by SmartSense | Food Safety, Supply Chain, Grocery, Food Service

Explore solutions built for your industry

Our customer-proven solutions monitor medications and food inventories for some of the most recognizable names in the industries of healthcare, food service, and transportation, and logistics. See how our solutions adapt to your industry needs.

SEE SOLUTIONSKroger Health Strengthens Compliance Visibility with SmartSense

Watch The VideoLEARN

Questions? Call +1 (866) 806-2653 to speak to our experts.

Schedule demoQuestions? Contact us.

Call +1 (866) 806-2653 to speak with our experts or get started with a demo.

CONTACT USAbout Us

SmartSense was created to use the power of the Internet of Things (IoT) to help our customers protect the assets most critical to the success of their business.

See our storyCONNECT. PROTECT. RESULTS.

Questions? Call +1 (866) 806-2653 to speak to our experts.

Schedule demoPlease select your login

April 13, 2023

The Role of IoT Sensing-as-a-Service in Combating Food Waste

In the United States alone, the FDA estimates that 30%–40% of the food supply is wasted. That’s approximately 35 million tons annually. Or on a more human scale, that’s 219 pounds of waste per person each year.

With record-high inflation rates increasing the potential for an economic recession, today’s consumers simply can’t afford to discard one-third of the food they purchase. Considering that global food prices are 34% more expensive year-over-year, food service companies — from restaurants to supermarkets — are in a powerful position to help their customers reduce food waste currently costing American families with children $1,900 per year on average.

The costs to climate and the environment

The costs of food waste extend beyond consumers to the much broader concerns of climate and environment. According to the U.S. Environmental Protection Agency, (EPA) America’s food waste footprint generates 170 million greenhouse gas emissions each year. That’s equal to the annual emissions of 42 coal-fired power plants. This alarming excess of CO2 is a key driver of the accelerating climate crisis afflicting every region nationwide. From raging forest fires on the West coast to devastating tornadoes in the Southeast, the proliferation of historic natural disasters requires urgent action to meet the Paris Agreement’s target of limiting global temperature increases to 1.5° C above pre-industrial levels.

Add to that the pressing issues of sustainability. The United Nations predicts that the population worldwide will reach 9.3 billion by 2050. Such massive growth will require global food production to increase by more than 50% from 2010 levels. Reducing food waste can mitigate a potential crisis of food scarcity by easing the pressure to ramp up food production at such unsustainable levels. According to the EPA, eliminating 50% of food waste could save enough energy to power 21.5 million homes for one year.

Now more than ever, adoption of Internet of Things (IoT) Sensing-as-a-Service solutions across food retail is an effective way to diminish the damaging effects of unnecessary food waste. Combining the power of artificial intelligence, machine learning, and prescriptive analytics, IoT Sensing-as-a-Service ensures continuous monitoring at each link in the food chain — the smartest investment you can make to increase energy conservation and reduce food waste.

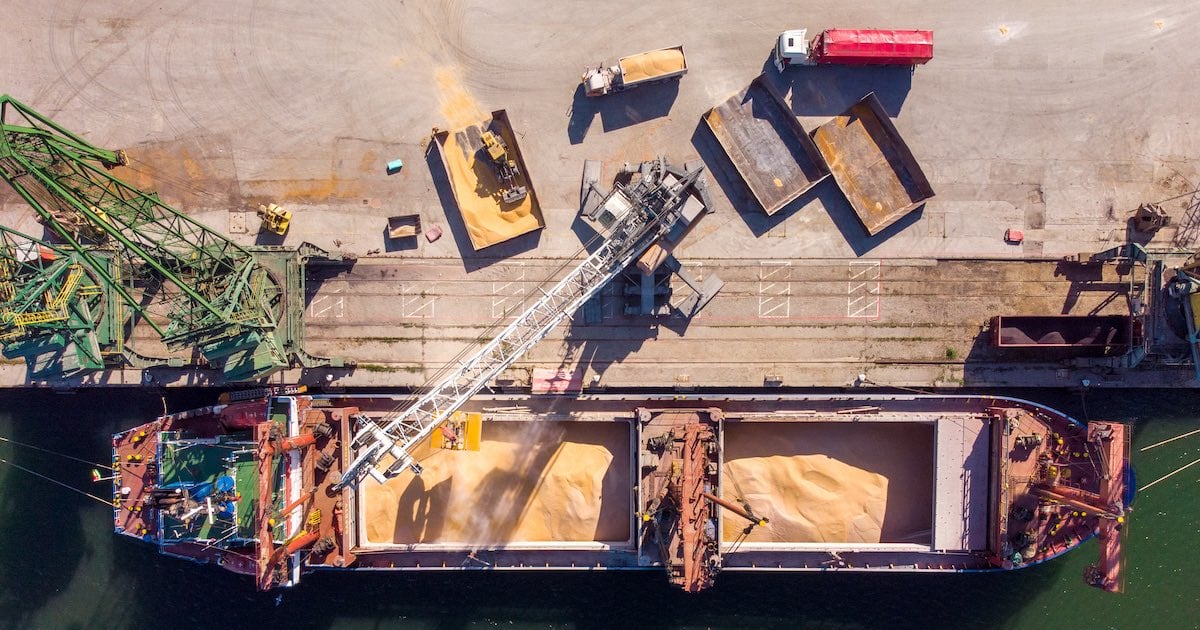

Food waste in the supply chain

Although a considerable amount of waste does occur in consumer households, much more is hidden throughout the food chain. Over 60% of food waste takes place in a commercial environment, including farms, manufacturing, food service, and retail. The scale of these operations accelerates the rate of waste so that most of it has already transpired by the time any single food is available in a grocer’s produce section or on a restaurant’s menu.

To maintain ripeness, perishable food products — such as an avocado or a banana — are kept dormant throughout the supply chain. They are later awakened with specific gases at specific times based on their estimated arrival at retail. This process occurs throughout transportation, warehousing, and backroom storage.

Sustaining a fragile ambient atmosphere is essential for protecting products and preserving their longevity. Perishable foods must maintain precise gas and humidity levels and temperatures to ensure quality. Considerations for airflow, refrigeration size and type, rotation schedule, and product placement all factor into an optimized, waste-reducing operation. Keeping food fresh and safe is an intricate operation requiring sophisticated processes and the right technology to optimize outcomes and reduce waste.

Optimal food waste management using IoT Sensing-as-a-Service

IoT Sensing-as-a-Service comprises more than just the deployment of physical sensing and monitoring devices. Think of it as an enhanced blueprint that goes far beyond simply tracking and tracing perishable food products. Through AI-enabled digital decisioning and digitalized task management, IoT Sensing-as-a-Service empowers organizations to leverage advanced inventory performance data to curtail waste reduction and boost loss prevention efforts.

Connecting refrigeration units, display cases, transportation pallets, and other equipment employed throughout the supply chain brings enhanced visibility to the status of food quality along each product’s journey. Placed inside food storage equipment at each touchpoint, IoT sensors remotely monitor temperature, humidity, and gas settings in real time to confirm various protocols are compliant. In addition, the sensors automatically track equipment performance to detect and predict maintenance problems that could lead to waste.

Here is where the blueprint becomes pro-activated. The raw physical data collected from each IoT device along the food chain is integrated into a prescriptive analytics platform that provides continuous feedback loops alerting employees about anomalous temperature excursions that could damage products. This key information is transformed into descriptive insights and prescriptive workflows. In other words, if an excursion occurs, the platform’s capabilities generate a series of simplified corrective actions.

Armed with these actionable and data-driven insights, employees accurately confirm products are being transported and stored under optimal conditions. Leveraging this real-time visibility into food quality allows retailers to ensure that products are sold before they reach peak-quality, so they stay fresh longer after being taken home by the consumer.

These heightened levels of accuracy and transparency empower enterprises to ensure compliance, thus reducing the risk of spoilage and loss simultaneously. Additional facilities, merchandizers, and business functions across the food chain benefit as well, given their access to a wider data ecosystem that helps avoid contamination, inventory disruptions, and negative customer experiences.

Festival Foods: A fresh approach to food waste

Festival Foods, a regional grocer operating 40 grocery stores across the state of Wisconsin, is taking a fresh approach to food waste reduction. The retailer placed SmartSense IoT sensors in each refrigerator and freezer unit in every store. These sensors continuously monitor and record temperature data, which is then transmitted to gateways that send it to a centralized SmartSense database.

The gateways operate using cellular technology that continuously collects and transmits data in real time. Because the gateways are backed up by batteries, Festival Foods monitors temperatures even during a network or power outage. Safety managers immediately and precisely determine when food products meet safety and quality standards and when they need to be replaced, setting priorities based on temperature excursions. As a result, the frequency of temperature-controlled product loss has been reduced substantially since Festival Foods implemented the SmartSense IoT solution.

In addition, headquarters staff remotely monitoring the SmartSense database sees when store-based equipment is starting to show early signs of mechanical problems and notify store personnel to take preventative action. Other benefits include the ability to extend product shelf life by keeping food at optimal temperatures throughout the day.

IoT Sensing-as-a-Service is a smart business investment. In terms of loss reduction, selling food that you would otherwise have discarded increases revenue. In terms of margin control, optimizing your assets through connected IoT improves your P&L. Festival Foods estimates it has realized a 300% ROI from the SmartSense solution, saving $3 for every $1 it invested by significantly reducing employee labor, preventing product loss, and optimizing asset set point and hold points — all while saving lives and making the world a better place.

Like Festival Foods, food service operations of all sorts and sizes can do their part to reduce food waste. Working together, they can help make the world a safer and healthier place by adopting a sustainable IoT Sensing-as-a-Service that curbs climate change and protects the environment, while keeping customers happy.

Other Suggested Posts

How Sales & Operations Planning Decisions Prevent Food Waste in the Supply Chain

Food waste along the wholesale and retail supply chain is often blamed on downstream operations failures. Its roots, however, oftentimes lie upstream. As we ...

How to Improve QSR Operations with IoT-Enabled Tools for Deskless Workers

As the demand for convenient, fast, and quality food continues to rise, small QSR chains face increasing pressure to deliver exceptional customer experiences ...

Why Customer Success Makes the Difference in Your Condition Monitoring Program

If your business objective is to implement an efficient and successful condition monitoring program, gone are the days of “set it and forget it.” Today’s savvy ...

Why K-12 School Cafeterias Are Automating Food Safety

During the COVID-19 pandemic, there were significant disruptions to K-12 school food services nationwide. School nutrition directors were forced to rapidly ...

Frozenomics: Why Freezers Are Becoming America's Financial Lifeline

When times get tough, Americans get creative with how they stretch budgets. That's why today's shoppers are fighting inflation and financial strain with an ...

Subscribe to the SmartSense Blog

Stay up-to-date on the evolution of IoT connectivity.

CONNECT. PROTECT. RESULTS.

Learn how our complete critical

environment monitoring solution will help you

connect and transform your business.

Call +1 (866) 806-2653 to speak with our industry

experts or get started by

requesting a demo.